Monocoque Construction in Architecture | Structural Shell Buildings Explained

We design carefully considered eco homes and luxury holiday homes that perform well, age gracefully, and make long-term financial sense. RIBA Chartered Architects.

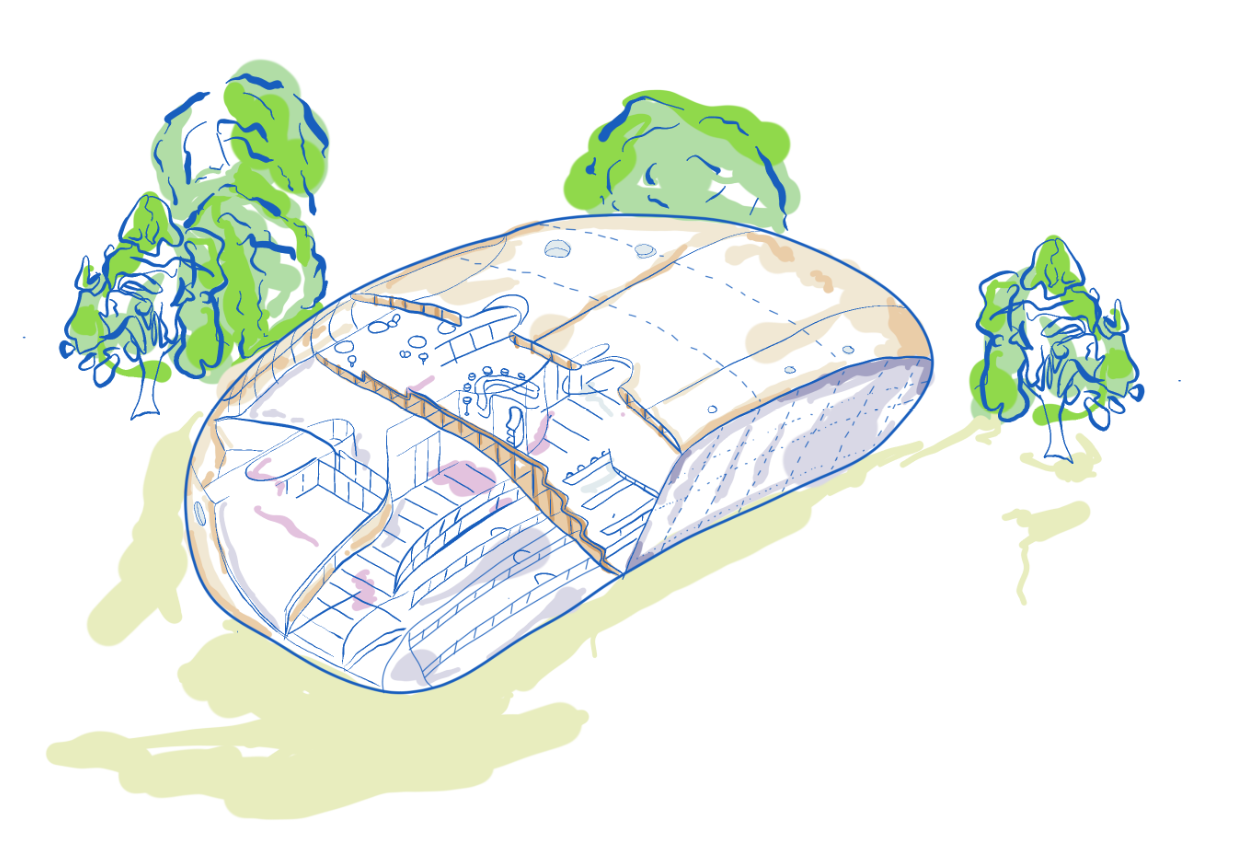

The Monocoque Cabin, an Airbnb retreat designed by Markos Design Workshop, demonstrates how a curving timber shell can serve as both the structure and the skin of a building. The entire exterior shell carries the load without a separate frame, allowing an open, airy interior for its compact footprint.

Introduction - Monocoque Construction in Architecture

Lightweight. Strong. Efficient. And assembled with precision.

Monocoque construction, developed and refined in aerospace and automotive engineering, is increasingly relevant to contemporary architecture. Unlike conventional framed buildings, which rely on an internal skeleton of columns, beams, and redundant structure, monocoque buildings distribute loads through the external shell itself. As with an eggshell or aircraft fuselage, structure and skin become one, allowing materials to work more efficiently and reducing overall weight.

For architects and clients working on modular buildings, cabins, and performance-led projects, this approach offers clear advantages. By minimising structural duplication and enabling off-site prefabrication, monocoque construction can reduce material use, shorten build programmes, and lower embodied carbon. When combined with Design for Manufacture and Assembly (DfMA), it supports greater precision, improved quality control, and forms that are difficult to achieve through traditional construction methods.

Historically, the adoption of monocoque construction in architecture has been limited by practical challenges within the construction industry, including fabrication complexity, regulatory interpretation, and a lack of established precedents. However, advances in digital design, engineered timber products, and off-site manufacturing are now making architectural monocoque systems viable, repeatable, and commercially realistic.

Monocoque architecture and structures is a process we established ourselves with the Monocoque Cabin, our award-winning prototype, which brings these principles to life in a real, buildable, rentable structure.

Workshop teams assembling the timber monocoque fuselage of a de Havilland Mosquito, a WWII aircraft that demonstrated the strength and efficiency of shell-based construction long before its adoption in modern architecture.

What is a Monocoque Structure?

Originally developed in early aerospace and automotive engineering, monocoque construction demonstrated that by eliminating redundant internal framing, structures could be made lighter, stronger, and more materially efficient. Instead of concentrating forces through discrete elements, loads are distributed across the surface of the shell, much like an eggshell or aircraft fuselage.

In architectural terms, this same principle is now being applied to buildings. When the envelope itself becomes the structure, it enables reduced material use, off-site fabrication, and highly efficient forms that are difficult to achieve through conventional framed construction. Advances in digital design, engineered materials, and manufacturing techniques have made monocoque construction a viable structural strategy for contemporary architecture, particularly in modular, prefabricated, and performance-led building types.

Speak to Peter the Architect

Book Your Free 20-Minute Project Strategy Call

If you’re exploring lightweight, efficient building methods, whether for modular homes, off-grid cabins or a bespoke architectural project, we are always interested in working on interesting construction methods and with interesting clients. On the call, we will look into:

The benefits of modern methods over traditional framing in cost, speed and sustainability

How digital fabrication and DfMA can reduce risk and improve accuracy

Realistic build costs based on our work with the Monocoque Cabin

The next step: feasibility, concept development or prototyping

Engineering Origins of Monocoque Construction

Monocoque construction first gained traction in engineering disciplines where reducing weight while maintaining structural stiffness was critical. In the early automotive industry, vehicles were traditionally built around a separate chassis, with the body acting largely as non-structural cladding. The shift to monocoque systems demonstrated that by integrating structure and skin into a single shell, redundant framing could be eliminated, resulting in lighter, more rigid, and more efficient structures.

A similar evolution occurred in aerospace engineering, where weight savings translated directly into performance. Aircraft designers moved away from internal frames with non-structural skins toward continuous, load-bearing fuselages. These systems showed that strength could be achieved through geometry, continuity, and material behaviour rather than mass alone. Thin shells, often formed from timber, composites, or engineered laminates, were able to withstand significant forces when properly designed.

Together, these engineering precedents established a principle that is directly relevant to architecture: a well-designed shell can outperform heavier, layered structural systems. By distributing loads across the surface rather than concentrating them in discrete elements, monocoque construction demonstrated how efficiency and performance can coexist. These lessons now inform architectural approaches where building envelopes are treated not as applied finishes, but as integral structural systems, particularly in prefabricated, modular, and performance-led buildings where material efficiency and precision are paramount.

Monocoque Construction in Architecture

In architectural terms, the key distinction between monocoque and traditional framed construction lies in how structural loads are carried. Conventional buildings rely on an internal framework of beams and columns, with the external envelope acting largely as non-structural cladding. In contrast, monocoque buildings use the external shell itself as the primary structural system, integrating structure and enclosure into a single working element.

This integration of form and structure allows materials to work more efficiently. Loads are distributed across the surface of the shell rather than concentrated at discrete points, reducing the need for redundant internal framing and enabling lighter, more continuous forms. In practice, this often results in fewer components, reduced material use, and improved structural clarity.

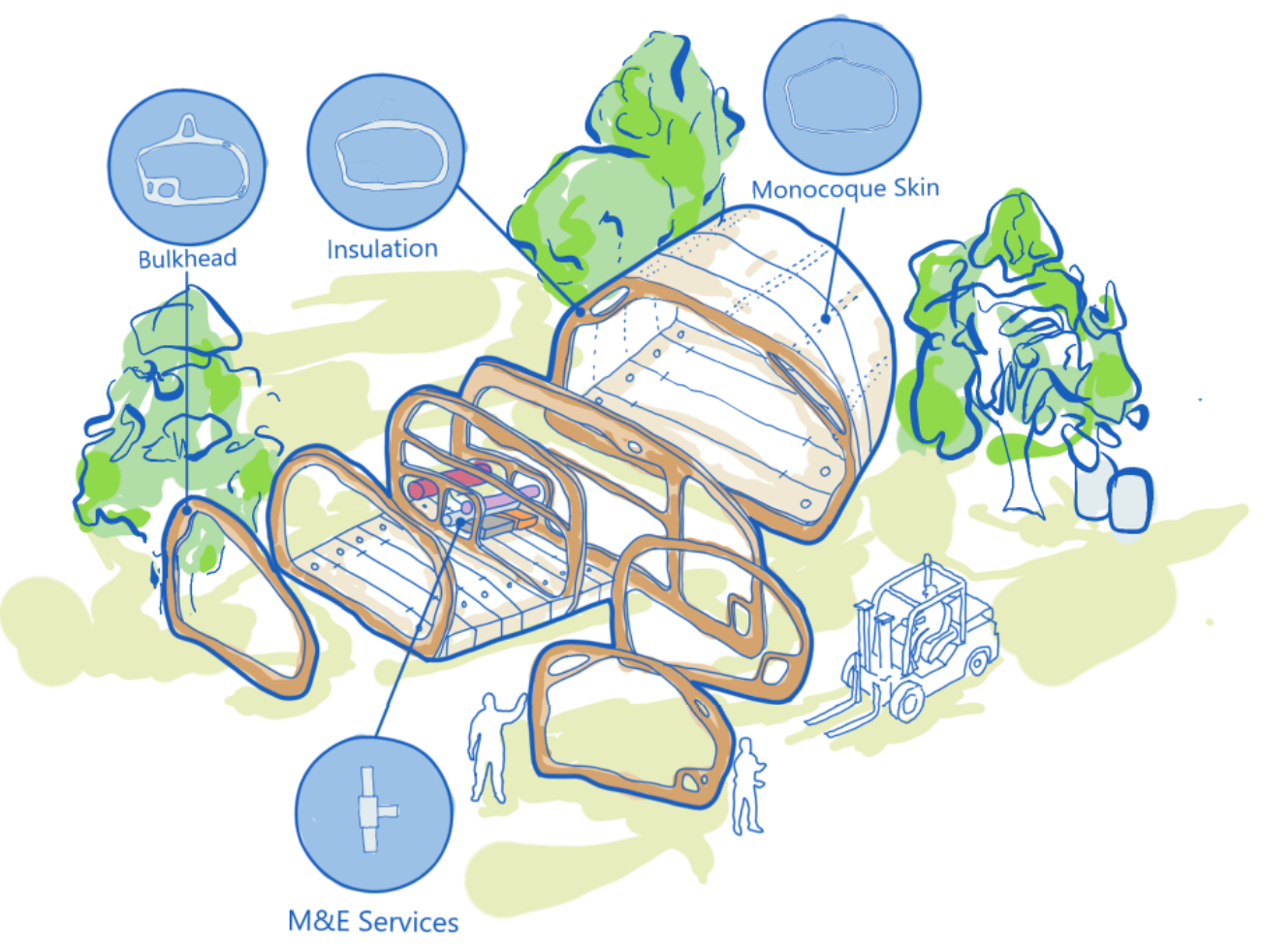

Conceptual diagram of a monocoque structural system for a small building. Instead of a separate frame and cladding, a series of rib-like timber frames (bulkheads) and a continuous outer skin work together to create a stiff shell. Even mechanical services and insulation can be integrated within the cavity of the shell, maximising space efficiency.

Monocoque construction is particularly well-suited to off-site fabrication and prefabrication. Because the structure is conceived as a complete shell rather than an assembly of independent elements, it can be digitally modelled, manufactured with high precision, and assembled rapidly on site. Structural bulkheads, insulation, and services can be integrated within the shell itself, maximising spatial efficiency and aligning closely with Design for Manufacture and Assembly (DfMA) principles.

From a sustainability perspective, monocoque systems typically perform well due to their reduced material demand and lower construction waste. Engineered timber products, such as plywood laminates and cross-laminated timber, are especially well suited to monocoque applications, offering high strength-to-weight ratios and strong environmental credentials. In some contexts, steel, aluminium, or composite materials may also be used where specific structural or durability requirements apply.

This cutaway sketch illustrates how the monocoque shell forms both the structure and the enclosure, eliminating internal framing and creating a lightweight, highly efficient architectural form.

However, monocoque construction is not a universal solution. Because the shell is structural, these systems require a high level of design resolution early in the process. Late-stage changes or post-construction alterations can compromise structural performance, placing greater emphasis on careful planning, coordination, and engineering input from the outset. This makes monocoque construction most appropriate for projects where geometry is well controlled and performance priorities are clearly defined.

In architectural practice, monocoque systems are most commonly applied to compact buildings such as cabins, modular housing, off-grid structures, and specialist prefabricated projects, where efficiency, transportability, and build speed are critical. When used appropriately, monocoque construction offers a precise, materially economical approach to building that integrates structure, enclosure, and performance into a single coherent system.

Conclusion: Monocoque as a Game-Changer in Structural Design

Monocoque construction offers a practical, sustainable approach to modern architecture. With better strength-to-weight performance, reduced waste, and elegant forms, monocoque systems are well-positioned to shape the next generation of eco-conscious building.

Want to experience a monocoque structure first-hand? Stay in our award-winning Monocoque Cabin.